Exhaust Fan is a specialized ventilation appliance designed to remove stale, polluted, or humid air from enclosed spaces, replacing it with fresh outdoor air to improve indoor air quality and maintain a comfortable environment. Unlike cooling fans (such as Stand Fans or Wall Fans) that circulate existing indoor air, an Exhaust Fan focuses on air extraction—effectively eliminating odors, moisture, smoke, and airborne contaminants from areas like kitchens, bathrooms, garages, workshops, and commercial spaces (e.g., restaurants, laundries, or factories).

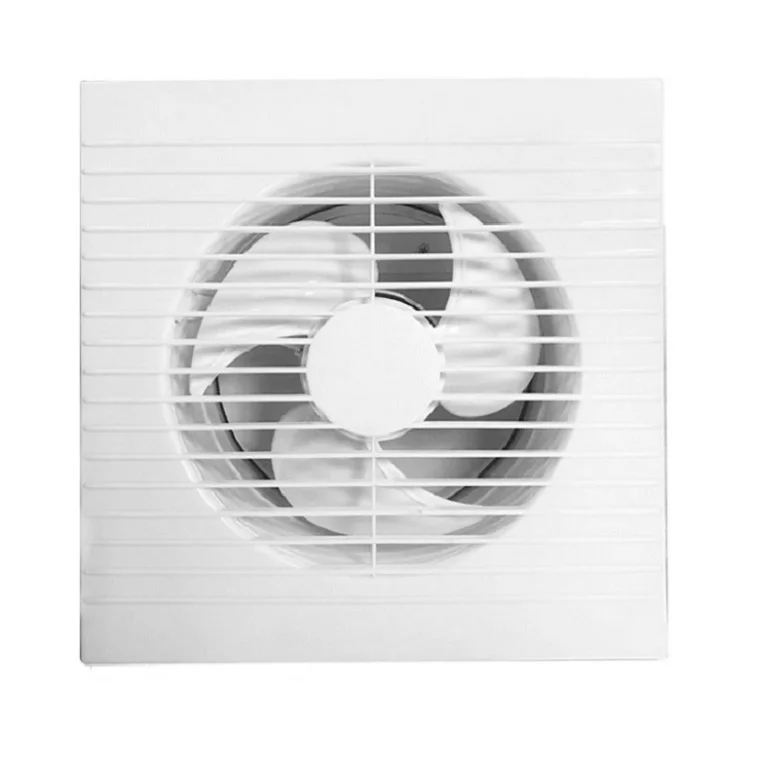

The core function of an Exhaust Fan is to create negative pressure within a room, which draws in fresh air from outside through windows, doors, or vents while pushing out unwanted air through a duct system (or directly outdoors for ductless models). This process is critical for spaces prone to high humidity (like bathrooms after showers) or strong odors (like kitchens during cooking), as stagnant air in these areas can lead to mold growth, mildew, peeling paint, or even respiratory discomfort. With various designs tailored to different spaces—including ceiling - mounted, wall - mounted, window - mounted, and inline (duct - integrated) models—Exhaust Fan meets the unique ventilation needs of both residential and commercial users.

In modern households and businesses, Exhaust Fan has become an essential appliance rather than a luxury. For homeowners, a bathroom Exhaust Fan prevents moisture buildup that damages walls and ceilings, while a kitchen Exhaust Fan removes cooking fumes, grease particles, and strong smells (e.g., from spices or fried food) that linger in the air. In commercial settings, such as restaurants, Exhaust Fan systems (often paired with hoods) are mandatory to comply with health and safety regulations, as they protect employees and customers from harmful fumes and maintain a clean air environment. Additionally, Exhaust Fan is energy - efficient compared to complex HVAC systems, making it a cost - effective solution for targeted ventilation.

This classification page provides a comprehensive overview of Exhaust Fan products, covering their key advantages, advanced craftsmanship, and essential features to help users select the right model for their needs. Whether you’re looking for a compact bathroom Exhaust Fan to reduce moisture or a powerful commercial - grade unit to handle heavy fumes, this page breaks down why Exhaust Fan is vital for air quality, how it outperforms other ventilation options, and what manufacturing techniques ensure its reliability and efficiency.

Advantage Points

Eliminates Moisture and Prevents Mold Growth: One of the most critical advantages of an Exhaust Fan is its ability to remove excess moisture from indoor spaces. Bathrooms, laundry rooms, and kitchens are prime areas for moisture buildup—for example, a 10 - minute hot shower can release up to 1.5 liters of water vapor into the air. Without proper ventilation, this moisture condenses on walls, ceilings, mirrors, and fixtures, creating a breeding ground for mold, mildew, and bacteria. An Exhaust Fan quickly extracts this moist air, reducing humidity levels to below 60% (the threshold for mold growth). By preventing mold and mildew, Exhaust Fan protects the structural integrity of your home (avoiding rotting wood, peeling paint, or damaged drywall) and safeguards your family’s health by reducing exposure to mold spores, which can trigger allergies, asthma, and other respiratory issues.

Removes Odors and Airborne Contaminants: Exhaust Fan is highly effective at eliminating persistent odors and harmful airborne particles that ordinary fans cannot address. In kitchens, cooking produces fumes, grease droplets, carbon monoxide (from gas stoves), and strong odors (e.g., from fish, garlic, or curry) that can seep into furniture, carpets, and fabrics. An Exhaust Fan (especially when paired with a range hood) captures these contaminants at the source and vents them outdoors, preventing odors from lingering or spreading to other rooms. In garages or workshops, Exhaust Fan removes fumes from gasoline, paint, solvents, or power tools—substances that can be toxic if inhaled long - term. For smokers, an Exhaust Fan in a designated smoking area quickly clears smoke and reduces the risk of secondhand smoke exposure for others.

Improves Indoor Air Quality and Enhances Comfort: By replacing stale, polluted air with fresh outdoor air, Exhaust Fan significantly improves indoor air quality. Stagnant air in enclosed spaces can accumulate dust mites, pet dander, volatile organic compounds (VOCs from cleaning products or furniture), and other allergens. An Exhaust Fan’s air - exchange process dilutes these contaminants, making the air healthier to breathe—particularly beneficial for individuals with allergies, asthma, or sensitivities to airborne irritants. Additionally, improved air circulation from Exhaust Fan reduces stuffiness, making rooms feel more comfortable even in moderate temperatures. For example, a kitchen with an Exhaust Fan feels cooler during cooking by removing hot, fume - filled air, while a bathroom with an Exhaust Fan feels fresher and less clammy after use.

Protects Home and Furniture from Damage: Excess moisture and airborne contaminants (like grease) can cause long - term damage to your home and belongings—damage that an Exhaust Fan helps prevent. In bathrooms, moisture can warp wooden cabinets, rust metal fixtures (e.g., towel racks or toilet paper holders), and discolor grout lines. In kitchens, grease particles from cooking settle on walls, cabinets, and appliances, creating a sticky film that is hard to clean and can stain surfaces over time. An Exhaust Fan removes these harmful elements before they can accumulate, extending the lifespan of your walls, ceilings, cabinets, and furniture. This not only saves you money on repair or replacement costs but also keeps your home looking cleaner and well - maintained for longer.

Energy - Efficient and Cost - Effective Ventilation: Compared to whole - house HVAC systems (which ventilate the entire home) or dehumidifiers (which only reduce moisture), Exhaust Fan offers targeted ventilation at a fraction of the energy cost. Most residential Exhaust Fan models consume just 10 to 50 watts of electricity—far less than an air conditioner (which uses 1,000+ watts) or a dehumidifier (which uses 300+ watts). Running an Exhaust Fan for 30 minutes after a shower or during cooking costs only a few cents per day, making it an affordable long - term solution. Additionally, Exhaust Fan reduces the workload on your HVAC system: by removing hot, humid air from kitchens or bathrooms, it helps your air conditioner cool the home more efficiently, lowering overall energy bills. The initial purchase price of an Exhaust Fan is also relatively low, and installation is straightforward (for most models), adding to its cost - effectiveness.

Quiet Operation for Undisturbed Use: Modern Exhaust Fan models are engineered for quiet operation, addressing the common complaint of loud, obtrusive ventilation units. Manufacturers use noise - reduction technologies such as insulated motor housings (which absorb sound), aerodynamic fan blades (which minimize air turbulence), and precision - balanced motors (which reduce vibration). As a result, most residential Exhaust Fan models produce between 20 to 40 decibels—equivalent to the sound of a quiet whisper or a ticking clock. This quiet performance is especially important for spaces like bathrooms (used at night) or bedrooms (for models installed in en - suites), where loud fans could disrupt sleep or relaxation. Even commercial - grade Exhaust Fan models (designed for heavy use) are built with noise controls to avoid disturbing employees or customers.

Craftsmanship Selling Points

High - Efficiency Motors for Powerful Airflow: The motor is the heart of an Exhaust Fan, and top - tier models feature high - efficiency motors designed for maximum airflow (measured in cubic feet per minute, CFM) and long - term durability. These motors use copper windings (instead of aluminum) for superior electrical conductivity and heat resistance—copper windings reduce energy loss, lower heat generation, and extend the motor’s lifespan. Many Exhaust Fan motors also include permanent split capacitor (PSC) technology, which ensures smooth startup, consistent performance, and reduced energy consumption compared to older motor designs. Additionally, motor housings are made from heat - resistant materials (e.g., aluminum alloy or high - grade plastic) with vented designs to dissipate heat, preventing overheating even during continuous use (e.g., in commercial kitchens). Rigorous testing during manufacturing ensures these motors can operate reliably for 10,000+ hours—equivalent to over 10 years of daily use.

Aerodynamic Fan Blades and Grilles for Optimal Airflow: The design of an Exhaust Fan’s blades and grilles directly impacts its airflow efficiency and noise level. High - quality Exhaust Fan models feature aerodynamically shaped fan blades—often curved or contoured to minimize air resistance while maximizing air displacement. These blades are precision - cut from lightweight, durable materials (e.g., ABS plastic or reinforced polypropylene) that resist warping, cracking, or damage from moisture. The grilles (both intake and exhaust) are also engineered for performance: intake grilles have wide, smooth openings to allow air to flow in without obstruction, while exhaust grilles (for ductless models) are designed to direct air outdoors without creating backdraft (which would push stale air back into the room). Some grilles also include removable filters (e.g., grease filters for kitchen Exhaust Fans) that trap particles before they enter the fan or duct system, making maintenance easier and protecting the motor from damage.

Duct Compatibility and Air Tightness for Effective Ventilation: For ducted Exhaust Fan models (the most common type for residential use), craftsmanship focuses on ensuring compatibility with standard duct sizes (e.g., 4 - inch, 6 - inch) and air tightness to prevent air leakage. Manufacturers use precision - molded duct connectors made from flexible yet durable materials (e.g., aluminum foil or plastic) that form a tight seal with the fan and ductwork. This air tightness is critical: even small leaks in the duct system can reduce the Exhaust Fan’s efficiency by allowing stale air to leak back into the room instead of venting outdoors. Some high - end models also include backdraft dampers—one - way valves that close when the fan is off to prevent outdoor air, pests, or rain from entering the duct and room. These dampers are made from corrosion - resistant materials (e.g., stainless steel) to withstand outdoor conditions and ensure long - term functionality.

Moisture - Resistant and Corrosion - Proof Construction: Since many Exhaust Fan models are used in high - humidity or greasy environments (e.g., bathrooms, kitchens), manufacturers use moisture - resistant and corrosion - proof materials to ensure durability. Fan housings for bathroom Exhaust Fans are made from UV - stabilized plastic or galvanized steel that resists rust, peeling, or warping when exposed to moisture. Kitchen Exhaust Fan components (e.g., grilles, filters, and motor housings) are coated with anti - grease or non - stick finishes that make cleaning easier and prevent grease buildup from damaging the fan. For outdoor or commercial use (e.g., warehouse Exhaust Fans), models may feature stainless steel frames and blades that resist corrosion from rain, humidity, or chemical fumes. All electrical components (e.g., wiring, switches, and capacitors) are sealed in moisture - proof enclosures to prevent short circuits or electrical damage—meeting IP (Ingress Protection) ratings like IP44 or higher for water and dust resistance.

User - Friendly Controls and Smart Features: Modern Exhaust Fan models integrate user - friendly controls and smart features that enhance convenience and efficiency, all built with durable components. Basic models include intuitive switches (e.g., wall - mounted toggles or pull cords) made from high - quality plastic that withstands repeated use and moisture. Advanced models may include humidity sensors—these automatically turn the fan on when humidity levels exceed a set threshold (e.g., 60%) and turn it off once levels drop, eliminating the need for manual operation (ideal for forgetful users). Some Exhaust Fan models also include motion sensors (which activate the fan when someone enters the room) or timer functions (allowing users to set the fan to run for 15, 30, or 60 minutes after use). For smart homes, Wi - Fi - enabled Exhaust Fan models let users control the fan via a smartphone app—adjusting speed, setting timers, or monitoring air quality remotely. These controls are built with durable, weather - resistant components to ensure reliability in high - moisture spaces.

Compliance with Strict Safety and Energy Standards: Top - quality Exhaust Fan products adhere to rigorous international safety and energy standards to ensure user protection and efficiency. Safety certifications include UL (Underwriters Laboratories) in the U.S., CE (Conformité Européenne) in Europe, and CCC (China Compulsory Certification) in China—these require testing for electrical safety (e.g., protection against shocks or short circuits), fire resistance (e.g., flame - retardant materials), and mechanical safety (e.g., secure fan blades that won’t detach). Energy efficiency standards, such as ENERGY STAR® in the U.S., recognize Exhaust Fan models that meet strict energy - saving criteria—these models consume up to 70% less energy than non - certified units while maintaining the same airflow performance. Additionally, for commercial Exhaust Fan systems (e.g., restaurant hood fans), compliance with local building codes (e.g., NFPA 96 in the U.S. for kitchen ventilation) ensures the fan can handle high temperatures and grease loads safely. These certifications give users confidence that their Exhaust Fan is safe, efficient, and built to last.