How Do Kitchen Fans Compare in Residential and Commercial Use?

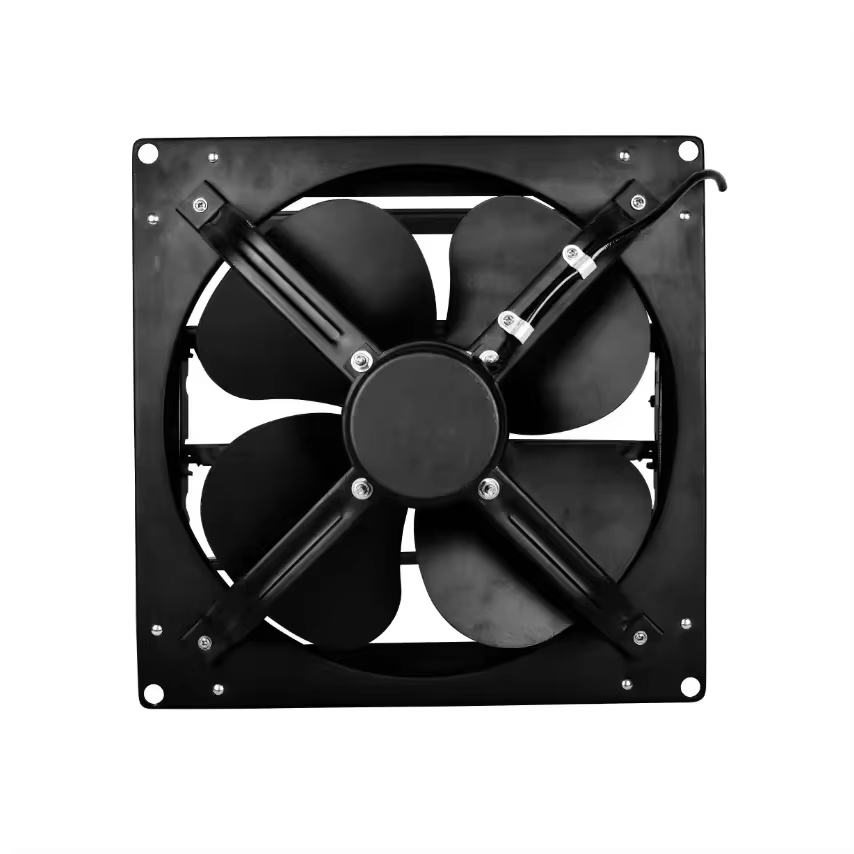

The difference in design for residential and commercial kitchen fans is determined mainly by design and functionality. For residential fans, the design is compact and attractive, since they need to blend into the overall kitchen design. Most of the house fans are small to mid-sized in dimension and come in basic color schemes like white, silver, and black, allowing seamless integration to different home settings. On the other hand, fans in commercial kitchens (for example in restos, hotels and catering factories) are built on a bigger and more robust scale because they need to withstand a higher heat and oil fume cooking level and require a stronger built, like reinforced fan housings and bigger fan blades. Moreover, commercial fans are more industrial in appearance, prioritizing functionality over aesthetics. Each design serves to fit the needs of the kitchen type, residential or commercial.

The Performance Expectations of Residential and Commercial Kitchen Fans

Increased cooking frequency, higher volume of oil fume, and larger spaces are the key differences that result in varying performance expectations of kitchen fans in residential and commercial settings.

In homes, range hoods and fans primarily serve to clear away the cooking oil and smells associated with family meal preparation, which happens less frequently and produces a smaller volume of oil vapors Therefore, range hoods and fans in homes do not require very powerful suction, 150 to 300 cubic meters per hour of airflow is adequate. In addition to this, fans in homes have to be quiet to not disrupt family activities in the house, which is why most home range hoods and fans operate below 60 decibels. In contrast, commercial kitchens operate long hours daily with several stovetops in use simultaneously, creating a significant volume of oil vapors, odor and heat. That is why commercial fans are built to exhaust in excess of 500 cubic meters per hour and in the case of larger ones, 1000 cubic meters per hour, thick walls of 1000 cubic meters per hour and greater. In the case of commercial kitchens. Unlike home kitchens, noise is less of a problem in commercial kitchens because the kitchen is usually isolated from seats and living spaces.

Different environmental factors determine the performance requirements for kitchen fans to ensuring they effectively serve their purpose.

Energy Efficiency & Cost of Operation for Kitchen Fans

When selecting kitchen fans, both residential and commercial users consider energy efficiency and the cost of operation, but their attention lies in different areas. For residential users, the focus is on the savings and efficiency of energy use for the kitchen fan over the long run, as kitchen fans are used for only a few hours a day and the cumulative energy use over time can impact a household. This is one of the reasons residential kitchen fans are equipped with energy-efficient motors (DC brushless motors), which can cut energy consumption for a home by 30%-50% in comparison to the traditional AC motors. Because the cost of electricity is very low (a few cents) for residential kitchen fans, their operating cost is low. In contrast, commercial kitchen fans have to run for 8 to 12 hours a day, or even more, and so the efficiency of the fan will have a direct impact on the operating cost of the business as well. Although commercial kitchen fans will still have to focus on energy efficiency, they often have to compromise energy efficiency for performance.Some high-end kitchen exhaust fans are designed with variable frequency technology and can save money by automatically adjusting speed according to oil fume volume. Nevertheless, large and powerful commercial kitchen fans will almost always cost more to run daily compared to residential fans, sometimes costing several dollars. Knowing the difference can help a user make a more appropriate cost-efficient kitchen fan choice.

Differences in the Maintenance and Cleaning Needs of Residential and Commercial Kitchen Fans

There are differences in the maintenance and cleaning of kitchen fans in residential and commercial settings, and it mainly depends on the intensity of use. Because kitchen fans in a home are less frequently used, cleaning takes place about every 1 to 3 months, and fan oil and dirt build up a lot less. Cleaning is also a more straightforward task since most fans allow for removable filter screens and fan blades, which can then be washed with soapy water and a brush. Residential fans only require a maintenance check of motor operation and a tightening of loose parts a couple times a year. Commercial fans are, by comparison, much more demanding.

Oil fumes create dirt and grime on the fan blades, on the housing, and in the ducts. If this dirt isn't removed, it can negatively impact the fan's performance, greatly increase the amount of energy used, and lead to potential fire risks. This is why the fans in commercial kitchens need to be cleaned at least weekly. Under some high-intensity use cases, they need to be cleaned every 2 to 3 days. These need more complex cleaning and almost always involve professional cleaning tools and the disassembly of some parts. The increased maintenance done on commercial kitchen fans must include the purposeful and scheduled lubrication of the motors, replacement of the filters, and checking the ducts to ensure the fans can run on a schedule and be dependable. These reminders on the different levels of maintenance and cleaning provide the users needed contingency while operating the kitchen fans.

The Installation Considerations for Kitchen Fans in Residential and Commercial Spaces

Because of different patterns in layout and design of the space, ventilation systems, and safety, installation considerations for kitchen fans diverge for residential and commercial space. In homes, kitchen fans are located simple above the stove, or located near windows, which makes the installation easy.

Most home kitchen fans are either mounted on the wall or ceiling, and a professional can complete the mount in a few hours. During installation, a professional takes care of the fan alignment with the stove ensuring optimal oil fume capture and checks the exhaust duct for blockages ensuring oil fume backflow is prevented. Also, a mounted residential kitchen fan's installation takes into account the wall or ceiling's load-bearing capacity. In comparison, the installation of kitchen fans in commercial spaces is more intricate, as it has to be incorporated into the entire kitchen ventilation system. This is because, in commercial settings, kitchen fans are typically used as a part of a centralized exhaust system which is made up of air ducts, oil filters, and fire dampers. Specialists who can meet commercial ventilation standards must perform the installation, which can take several days. One of the biggest factors to take into account is whether the fan's air volume is appropriate for the size of the kitchen. In addition to that, the exhaust duct must be designed to deal with vast volumes of oil fume and must be fitted with fire-proof and oil-proof materials. Finally, to avoid legal complications, installation must meet local building codes as well as health standards.

These differences in how fans are installed help guarantee that kitchen fans are in and functioning safely in a variety of locations.

Tips on How to Choose the Appropriate Kitchen Fan for Residential and Commercial Purposes

When it comes to residential and commercial purposes, the most important thing to consider is the use. For residential purposes, the first thing to consider is the size of the kitchen. For small kitchens (less than 10 square meters) a kitchen fan with an air suction power of 150 to 200 cubic meters per hour is sufficient, whereas for larger kitchens (10 to 20 square meters) an air volume of 200 to 300 cubic meters per hour is required. Next, consider the noise the fan makes. To maintain a peaceful home, the fan noise level should be under 55 decibels. Lastly, consider how the fan is cleaned. Having detachable parts will help with regular cleaning. For commercial purposes the first thing to consider is to have high performance, for example an air suction power of more than 500 cubic meters per hour and strong suction power to get rid oil fumes.

When durability comes to mind, consider materials like stainless steel, which withstands high temperatures and resists corrosion. This will withstand the rigors of a commercial kitchen. Next, ensure the kitchen fan will work with the commercial kitchen ventilation system to avoid any issues during installation. Furthermore, both residential and commercial customers need to choose fans from reputable brands. An example would be https://www.kanasifans.com/, which offers quality products and reliable after-sales service. These suggestions will ensure that customers choose the right kitchen fan that meets their specific requirements.